Universal Welcomes Chris Thompson as Director of Sales and Marketing: Enhancing Customer Experience and Expanding Opportunities

|

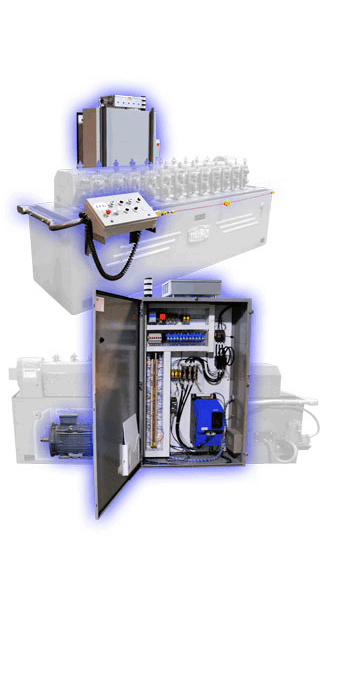

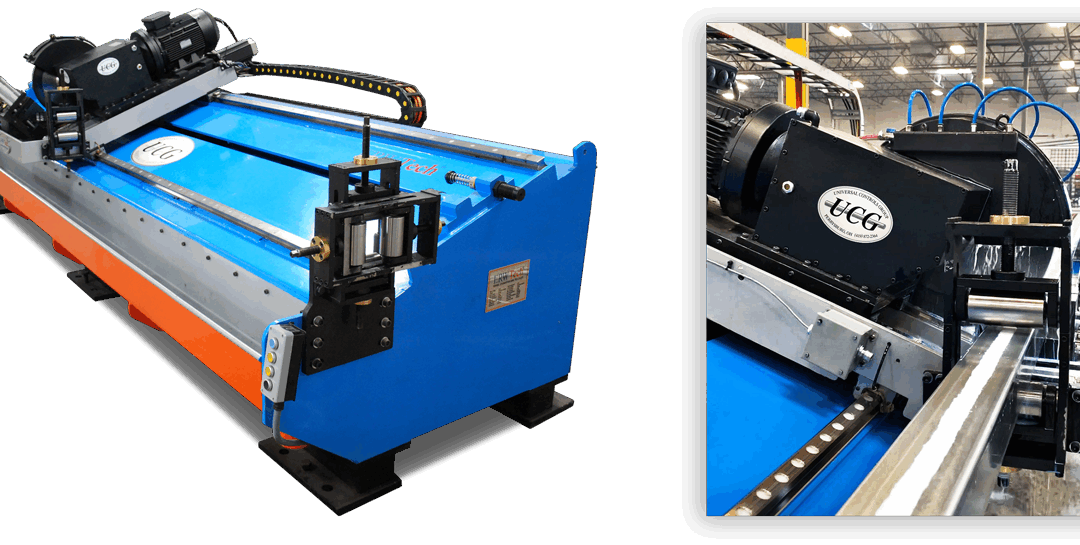

| We are delighted to share some exciting news with you. Universal has welcomed Chris Thompson as our new Director of Sales and Marketing. With extensive experience in the industrial automation and machinery sales since 2002, Chris has consistently excelled in sales and account management roles, ensuring customer satisfaction at every step. In 2019, Chris expanded his expertise to include management and marketing, showcasing his ability to seamlessly integrate these critical functions. This means you can expect a more cohesive and targeted approach to meeting your needs. Chris’s experience will be invaluable in enhancing our equipment offerings, providing you with more options and value. Chris will also lead our customer outreach and new business acquisition efforts. His focus on creating stronger connections and uncovering new opportunities ensures that your needs are understood and met effectively. Additionally, his commitment to streamlining our processes means improved efficiency and an even higher level of service for you. We are confident that Chris Thompson’s leadership and vision will bring significant benefits to you, our valued customers. We look forward to the positive impact he will make and the continued growth and innovation at Universal. For any inquiries or to connect with Chris directly, please contact him at +1 (419) 872-2364 or chris@utubeonline.com. Universal has grown considerably over the years, offering one of the largest inventories of new and used industrial metalworking machinery. Our services include machine reconditioning, new controls and drive systems, start-up and commissioning, as well as buying and selling options for your surplus machinery. Founded in 1984 by Ralph Girkins, Universal Tube & Rollform Equipment has always been committed to being the number one supplier of tube, pipe, and roll form machinery. Our extensive inventory includes tube mills, cut-offs, re-cut systems, rollformers, coil-handling machinery, and more. Our machinery can be sold as-is or reconditioned by our team, who can replace gearboxes, add new electrics, integrate machinery into production lines, and much more. We can also create custom tube mill or rollform lines using machinery from our inventory and/or new machinery manufactured by Universal Controls Group (UCG) and ERWTech. Send us a drawing of the shape you need to fabricate, and we can assemble a complete line quotation to produce the part you need. In 2020, UCG acquired Universal Tube & Rollform Equipment, combining our two companies into one great team. We continuously strive to grow our product and service capabilities to meet the needs of our ever-expanding and diverse customer base. +1 (419) 872-2364 |