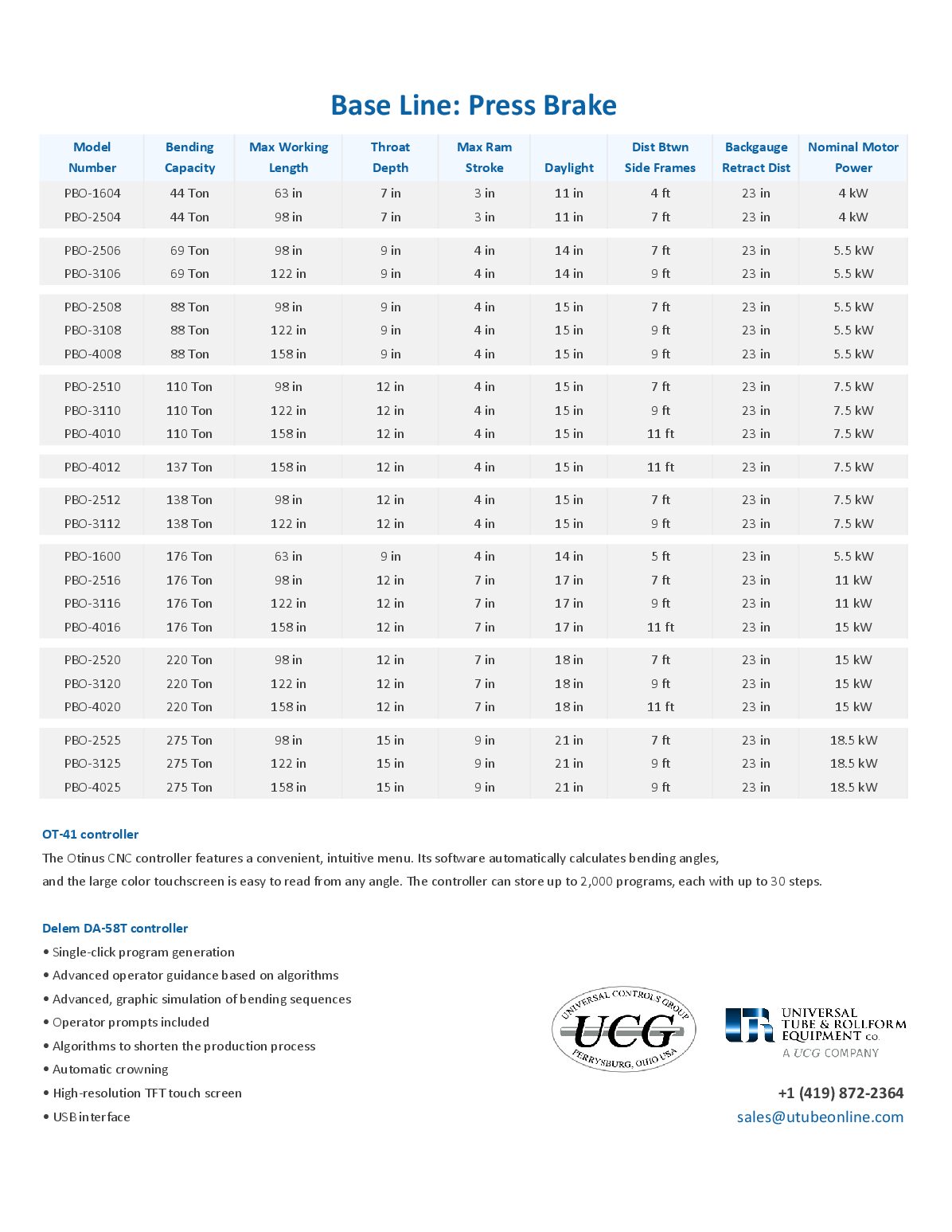

Base Line:

| Model Number | Bending Capacity | Max Working Length | Throat Depth | Max Ram Stroke | Daylight | Dist Btwn Side Frames | Backgauge Retract Dist | Nominal Motor Power |

| PBO-1604 | 44 Ton | 63 in | 7 in | 3 in | 11 in | 4 ft | 23 in | 4 kW |

| PBO-2504 | 44 Ton | 98 in | 7 in | 3 in | 11 in | 7 ft | 23 in | 4 kW |

| PBO-2506 | 69 Ton | 98 in | 9 in | 4 in | 14 in | 7 ft | 23 in | 5.5 kW |

| PBO-3106 | 69 Ton | 122 in | 9 in | 4 in | 14 in | 9 ft | 23 in | 5.5 kW |

| PBO-2508 | 88 Ton | 98 in | 9 in | 4 in | 15 in | 7 ft | 23 in | 5.5 kW |

| PBO-3108 | 88 Ton | 122 in | 9 in | 4 in | 15 in | 9 ft | 23 in | 5.5 kW |

| PBO-4008 | 88 Ton | 158 in | 9 in | 4 in | 15 in | 9 ft | 23 in | 5.5 kW |

| PBO-2510 | 110 Ton | 98 in | 12 in | 4 in | 15 in | 7 ft | 23 in | 7.5 kW |

| PBO-3110 | 110 Ton | 122 in | 12 in | 4 in | 15 in | 9 ft | 23 in | 7.5 kW |

| PBO-4010 | 110 Ton | 158 in | 12 in | 4 in | 15 in | 11 ft | 23 in | 7.5 kW |

| PBO-4012 | 137 Ton | 158 in | 12 in | 4 in | 15 in | 11 ft | 23 in | 7.5 kW |

| PBO-2512 | 138 Ton | 98 in | 12 in | 4 in | 15 in | 7 ft | 23 in | 7.5 kW |

| PBO-3112 | 138 Ton | 122 in | 12 in | 4 in | 15 in | 9 ft | 23 in | 7.5 kW |

| PBO-1600 | 176 Ton | 63 in | 9 in | 4 in | 14 in | 5 ft | 23 in | 5.5 kW |

| PBO-2516 | 176 Ton | 98 in | 12 in | 7 in | 17 in | 7 ft | 23 in | 11 kW |

| PBO-3116 | 176 Ton | 122 in | 12 in | 7 in | 17 in | 9 ft | 23 in | 11 kW |

| PBO-4016 | 176 Ton | 158 in | 12 in | 7 in | 17 in | 11 ft | 23 in | 15 kW |

| PBO-2520 | 220 Ton | 98 in | 12 in | 7 in | 18 in | 7 ft | 23 in | 15 kW |

| PBO-3120 | 220 Ton | 122 in | 12 in | 7 in | 18 in | 9 ft | 23 in | 15 kW |

| PBO-4020 | 220 Ton | 158 in | 12 in | 7 in | 18 in | 11 ft | 23 in | 15 kW |

| PBO-2525 | 275 Ton | 98 in | 15 in | 9 in | 21 in | 7 ft | 23 in | 18.5 kW |

| PBO-3125 | 275 Ton | 122 in | 15 in | 9 in | 21 in | 9 ft | 23 in | 18.5 kW |

| PBO-4025 | 275 Ton | 158 in | 15 in | 9 in | 21 in | 9 ft | 23 in | 18.5 kW |

Working table lengths: from 4 feet to 20 feet

Front laser safety system: Fiessler AKAS-II (Germany)

Hydraulic system: HAWE (Germany)

Front supports on linear guides

Universal lower die

Amada-Promecam tool clamping system

Quick clamping system

Movements in all axes controlled by servomotors

Front supports for sheet handling

Oil cooling system (OCS)

Light curtains

Limit switches

Safety guards

Lower die segmented as the upper die + die holder

AMADA type double punch clamping

Independent control of Y1 and Y2 axes

Automatic control of R-axis

2 front supports on linear guides

Optional Equipment:

Manual crowning

Automatic crowning

OT-41 controller:

The Otinus CNC controller features a convenient, intuitive menu. Its software automatically calculates bending angles,

and the large color touchscreen is easy to read from any angle. The controller can store up to 2,000 programs, each with up to 30 steps.

Delem DA-58T controller:

• Single-click program generation

• Advanced operator guidance based on algorithms

• Advanced, graphic simulation of bending sequences

• Operator prompts included

• Algorithms to shorten the production process

• Automatic crowning

• High-resolution TFT touch screen

• USB interface

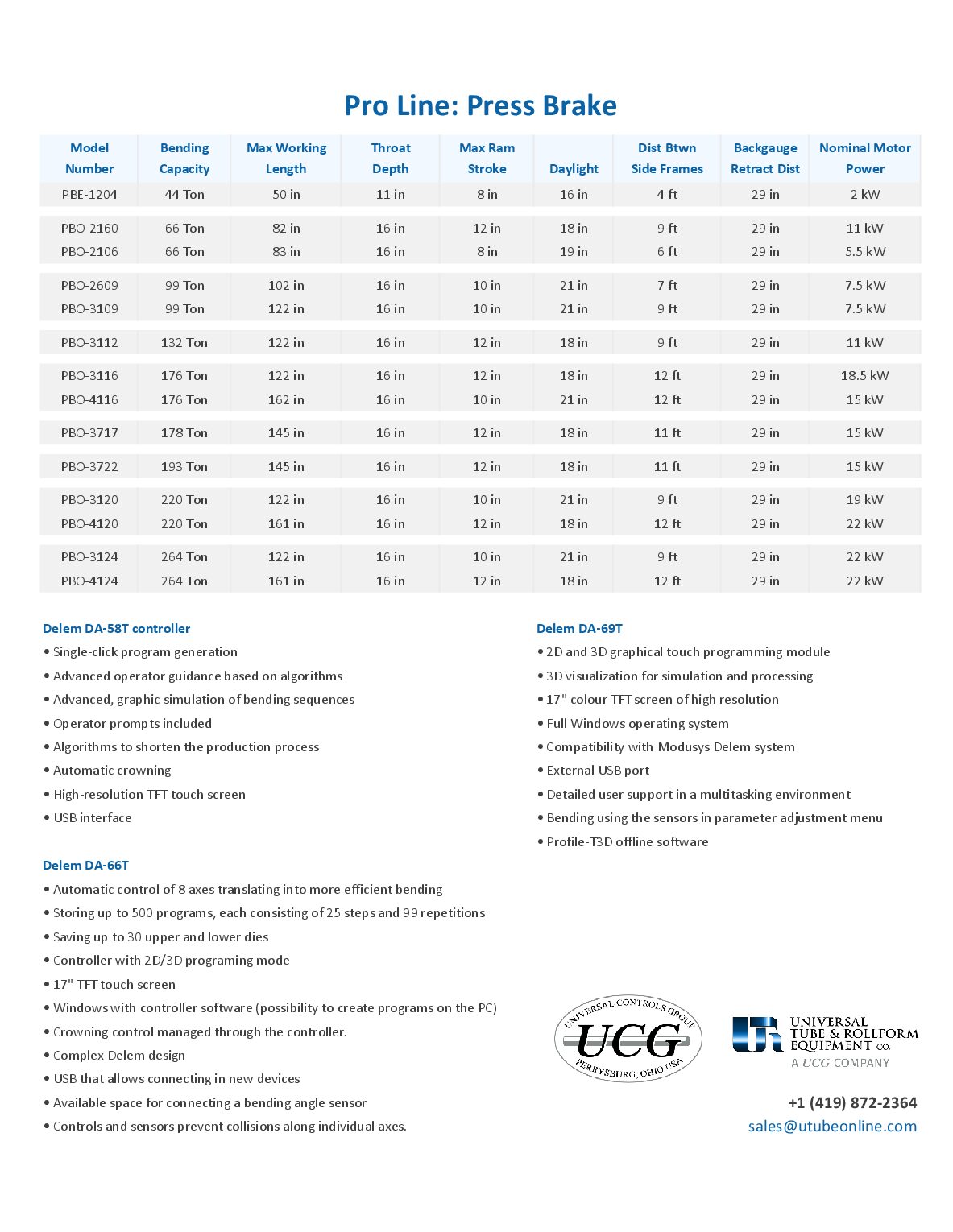

Pro Line:

| Model Number | Bending Capacity | Max Working Length | Throat Depth | Max Ram Stroke | Daylight | Dist Btwn Side Frames | Backgauge Retract Dist | Nominal Motor Power |

| PBE-1204 | 44 Ton | 50 in | 11 in | 8 in | 16 in | 4 ft | 29 in | 2 kW |

| PBO-2160 | 66 Ton | 82 in | 16 in | 12 in | 18 in | 9 ft | 29 in | 11 kW |

| PBO-2106 | 66 Ton | 83 in | 16 in | 8 in | 19 in | 6 ft | 29 in | 5.5 kW |

| PBO-2609 | 99 Ton | 102 in | 16 in | 10 in | 21 in | 7 ft | 29 in | 7.5 kW |

| PBO-3109 | 99 Ton | 122 in | 16 in | 10 in | 21 in | 9 ft | 29 in | 7.5 kW |

| PBO-3112 | 132 Ton | 122 in | 16 in | 12 in | 18 in | 9 ft | 29 in | 11 kW |

| PBO-3116 | 176 Ton | 122 in | 16 in | 12 in | 18 in | 12 ft | 29 in | 18.5 kW |

| PBO-4116 | 176 Ton | 162 in | 16 in | 10 in | 21 in | 12 ft | 29 in | 15 kW |

| PBO-3717 | 178 Ton | 145 in | 16 in | 12 in | 18 in | 11 ft | 29 in | 15 kW |

| PBO-3722 | 193 Ton | 145 in | 16 in | 12 in | 18 in | 11 ft | 29 in | 15 kW |

| PBO-3120 | 220 Ton | 122 in | 16 in | 10 in | 21 in | 9 ft | 29 in | 19 kW |

| PBO-4120 | 220 Ton | 161 in | 16 in | 12 in | 18 in | 12 ft | 29 in | 22 kW |

| PBO-3124 | 264 Ton | 122 in | 16 in | 10 in | 21 in | 9 ft | 29 in | 22 kW |

| PBO-4124 | 264 Ton | 161 in | 16 in | 12 in | 18 in | 12 ft | 29 in | 22 kW |

Working table lengths: from 4 feet up to 20 feet

Bending force: from 40 tones up to 880 tones

Controllers: Delem DA-66T or DA-69T

Axis number variation: from 4+1 up to 8+1

Fiessler Akas light curtains

Amada-Promecam tool clamping system

Quick clamping system

Movements in all axes controlled by servomotors

User-friendly interface

Front supports for sheet handling

Oil cooling system (OCS)

Hydraulic system: HAWE (Germany)

Light curtains

Limit switches

Safety guards

Automatic crowning

Promecam rapid clamp system

2 backgauge fingers

2 front supports on linear guides

AKAS II light curtains

Optional Equipment:

Controller: Delem DA-69T

2 front supports on linear guides

Delem DA-58T controller:

• Single-click program generation

• Advanced operator guidance based on algorithms

• Advanced, graphic simulation of bending sequences

• Operator prompts included

• Algorithms to shorten the production process

• Automatic crowning

• High-resolution TFT touch screen

• USB interface

Delem DA-66T controller:

• Automatic control of 8 axes translating into more efficient bending

• Storing up to 500 programs, each consisting of 25 steps and 99 repetitions

• Saving up to 30 upper and lower dies

• Controller with 2D/3D programing mode +1 (419) 872-2364

• 17″ TFT touch screen sa***@*********ne.com

• Windows with controller software (possibility to create programs on the PC)

• Crowning control managed through the controller.

• Complex Delem design

• USB that allows connecting in new devices

• Available space for connecting a bending angle sensor

• Controls and sensors prevent collisions along individual axes.

Delem DA-69T controller:

• 2D and 3D graphical touch programming module

• 3D visualization for simulation and processing

• 17″ colour TFT screen of high resolution

• Full Windows operating system

• Compatibility with the Modusys Delem system (modular scalability and adaptability)

• External USB port

• Detailed user support in a multitasking environment

• Bending using the sensors in parameter adjustment menu

• Profile-T3D offline software

Otinus manufactures high-quality equipment, including laser tube cutting machines, shears, laser cutting machines, and other essential tools designed for performance, safety, and efficiency. Known for their reliable, practical design, Otinus machines help fabricators achieve precise results and boost overall production capabilities. Together, we deliver durable, cost-effective solutions backed by expert support to meet the demands of modern manufacturing.

As an authorized supplier of Otinus fabricating machinery, we provide access to a wide range of new industrial metal fabrication equipment along with our full inventory of new and used tube mill lines, rollforming lines, automation solutions, parts, and expert support. Everything you need, all from one source.

Searching for a Specific Machine?

Our inventory is always changing. Contact us for help finding the machinery you need. We offer new machinery options tailored to your requirements.

Automation Solutions

We design, manufacture, and install control panels, drive systems, die accelerators, and other components for industrial metalworking machinery. Our team has over a century of experience specializing in tube, pipe, and rollform machinery. We deliver efficient and economical automation solutions worldwide.

Start-Up and Service Support

Our in-house engineering and service team offers installation management, start-up, commissioning, operator training, on-site service, and technical support. We prioritize quick machinery implementation and ongoing assistance to maintain efficiency.

Parts and Consumables

To minimize downtime, we stock common replacement parts at our Perrysburg, Ohio warehouse. Our team ensures prompt delivery to keep your operations running smoothly.

Machinery Reconditioning Services

We offer machine reconditioning and rebuilding services, updating to the latest technology, expanding capabilities, and improving performance. Reusing your equipment increases value, ensures accuracy, enhances safety, and eases operation.

Selling Your Machinery Made Easy

We purchase tube mills, rollformers, coil handling machinery, and other industrial metalworking machinery. Selling options include cash sale, trade-in, consignment, and auction. Contact us to learn more about our services and selling options.

Care is taken to provide a reliable description of this New Otinus Press Brake, but please note that these descriptions are not guaranteed. Prospective purchasers are encouraged to verify crucial details. We reserve the right to correct typographical errors. Please read the terms and conditions of sale pertaining to this New Otinus Press Brake. Please be aware that all machinery is subject to prior sale.