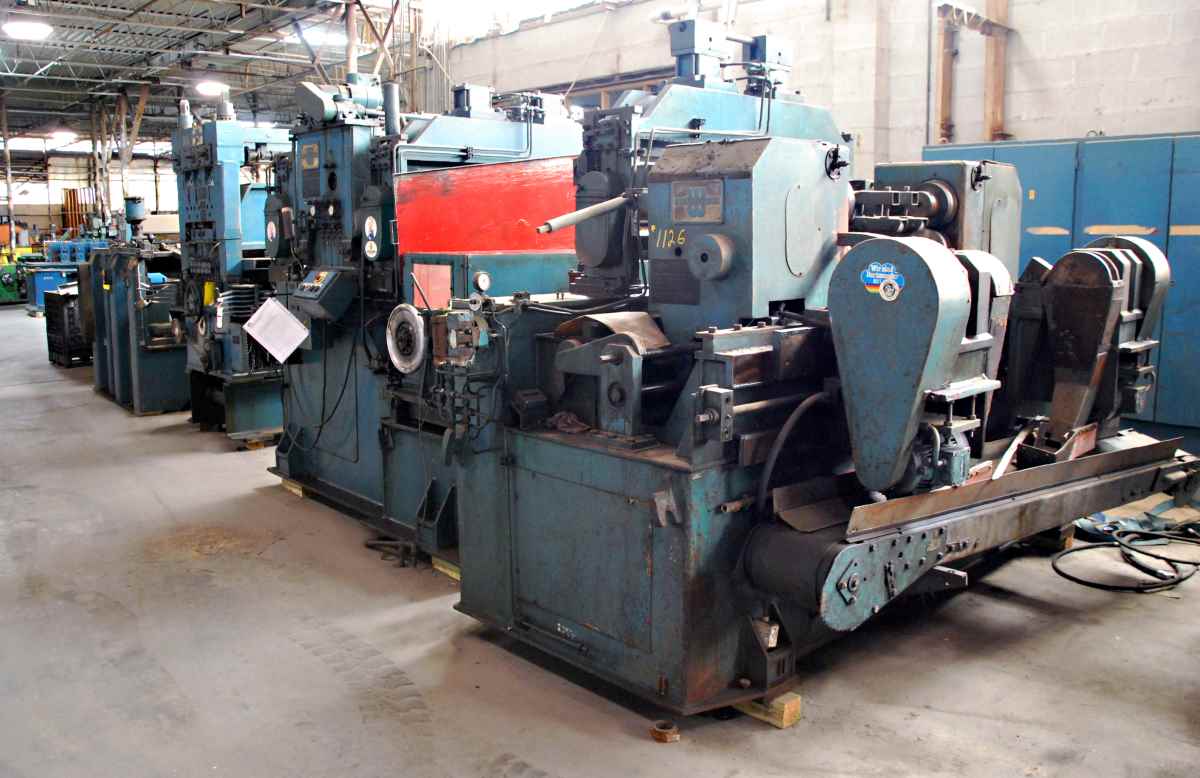

UTUBE NUMBER: 1126

MANUFACTURER: WILHELMSBURGER

SERIAL NUMBER: 2971

YEAR: 1972

SPECIFICATIONS:

Maximum Width: 51" (1300 mm)

Minimum Width: 16" (400 mm)

Gauge Thickness: .080" (2.00 mm)

Line Speed: 96 FPM (30 M/Min.)

Maximum Cut Length: 10′ (3 M)

EQUIPPED WITH:

Entry Pinch Rolls

Hydraulically Operated Entry Pinch Rolls Backed Up Over 2 Flights

Edge Trimmer:

Width: 16" – 52" (400 mm – 1300 mm)

Arbor Diameters: 3.15" (80 mm)

Cutter Detail: 7.87" x .80" (200 mm x 20 mm)

Speed: 96 FPM (30 M/Min.)

Gauge: .020" – .080" (0.63 mm – 2 mm)

Twin Rotary Chopper

Leveler:

Maximum Width: 51" (1300 mm)

Minimum Width: 16" (400 mm)

Type: 8 Roll (4 over 4)

Work Roll Dia.: 2.25" (55 mm)

Back Ups: 3 Flights Top and Bottom

Electric Screwdowns:

Driven Pinch Rolls: 5-1/2" (140 mm) Dia. Entry and Exit

Hydraulically Operated and Backed Up

Over 2 Flights

Flying Shear:

Travel: 52" (1320 mm)

Gauge Thickness: .080" (2.00 mm)

Fully Automatic Upcut Flying Shear Matched to Leveler

Electrical:

Dedicated Modern Electrical Control Gear Offering All the Facilities of a Fully Automated Cut to Length.

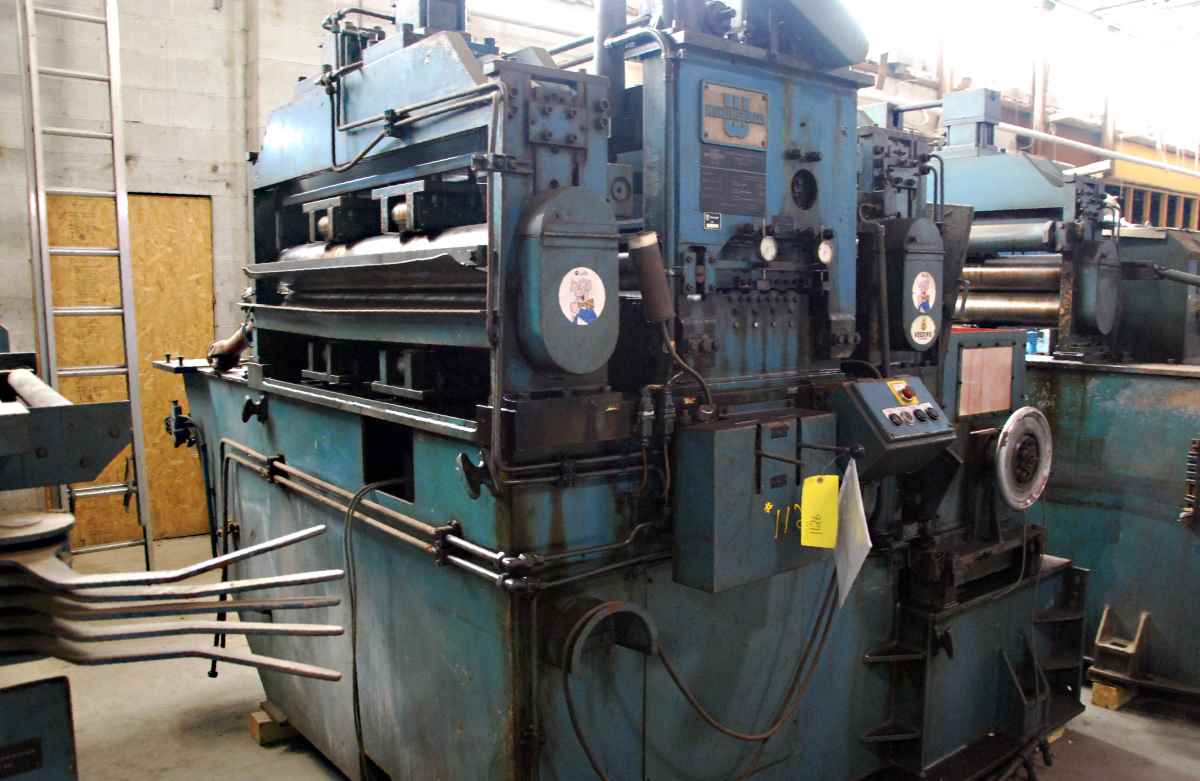

WILHELMSBURGER Sheet Leveler:

21 Roll Precision Sheet Leveler (11 over 11)

Work Roll Diameter: 1.38" (35 mm)

Back Ups: 5 Flights Top & Bottom

Roll Face Width: 51" (1300 mm)

Maximum Capacity: 060" (1.5 mm)

Line Speed: 13 – 42 M/Min.

Screwdown: Manual c/w DTI Readouts

Back Up Rolls Adjustment: Manual to All Bottom Flights

Main Drive: 22 Kw, 1460 RPM

Pass Line Height: 1225 mm

Full Roll Banking & Tilting Facility in 2 Sections Over 3 Sets of Work Rolls and 8 Sets of Work Rolls Respectively.

All Rolls & Bearings Piped for Forced Lubrication.

NOTE: No Uncoiler is included in this line

OVERALL DIMENSIONS: Multiple Pieces, 2 Truckloads

APPROXIMATE WEIGHT: 65,000 Lbs.

LOCATION: Universal Warehouse, Perrysburg, Ohio

CARE IS TAKEN TO GIVE A RELIABLE DESCRIPTION OF THIS USED CUT TO LENGTH LINE BUT THESE ARE NOT GUARANTEED. PROSPECTIVE PURCHASERS ARE ADVISED TO CHECK VITAL DETAILS. WE RESERVE THE RIGHT TO CORRECT STENOGRAPHIC ERRORS. ALL MACHINERY IS SUBJECT TO PRIOR SALE. CLICK HERE TO READ THE TERMS AND CONDITIONS OF SALE THAT APPLY TO THIS USED CUT TO LENGTH LINE. VISIT UNIVERSALCONTROLSGROUP.COM FOR INFORMATION ON NEW CONTROL PANELS, DRIVE SYSTEMS AND PLANT AUTOMATION.