UTUBE NUMBER: 1188

MANUFACTURER: ARDCOR

MODEL NUMBER: U-1

YEAR: 1967

SPECIFICATIONS:

Maximum Tube Diameter: 1-1/2″ (38.1 mm)

Minimum Tube Diameter: 3/4″ (19.05 mm)

Maximum Wall Thickness: .134″ (3.40 mm)

Minimum Wall Thickness: .034″ (.863 mm)

Vertical Adjustment: 4″ – 8-5/8″ (101.6 mm – 219.1 mm)

Horizontal Centers: 16″(406.4 mm)

Roll Space: 6″ (152.4 mm)

Spindle Diameter: 2″ (50.8 mm)

Center of Lower Spindle to Base: 7-1/2″ (190.5 mm)

Worm Gear Ratio: 14.5:1

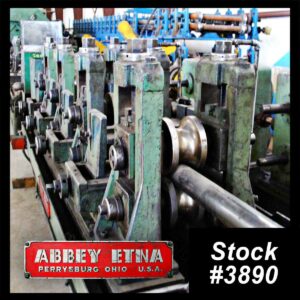

FORMING MILL:

(6) Driven Break Down Stands

(3) Driven Fins Stands

(1) 40 HP DC 500 Volt Motor

WELDING:

(1) 2-Roll Weld Pressure

(1) Seam Ironing Pass

SIZING MILL:

(4) Driven Sizing Stands

(4) Idle Side Rolls

(2) 2-Roll Straightening Units

(1) 25 HP DC 500 Volt Motor

TOOLING: 1.315″ (33.4 mm) On Mill

NOTE: MILL ONLY, NO ENTRY, WELDER OR CUT-OFF

OVERALL DIMENSIONS: Multiple Pieces, 1 Truckload

APPROXIMATE WEIGHT: 40,000 Lbs.

LOCATION: Universal Warehouse, Perrysburg, Ohio

Looking for a Specific Machine? Our inventory is always changing, contact us for help finding the machinery you need. We also offer new machinery options to meet your specific requirements.

Automation: We design, manufacture, and install control panels, drive systems, die accelerators, and other integral components for industrial metalworking machinery. Our knowledgeable team has over a century of collective experience specializing in tube, pipe, and rollform machinery, allowing us to deliver efficient and economical automation solutions to metal-forming manufacturers worldwide.

Start-Up and Service: Our in-house engineering and service team offers comprehensive support, including installation management, start-up and commissioning, operator training, on-site service, technical support, and more. We ensure prompt machinery implementation and offer ongoing support to maintain its efficiency over time.

Parts and Consumables: We stock common replacement parts at our Perrysburg, Ohio warehouse to minimize downtime and ensure your long-term efficiency.

Reconditioning: We offer machine reconditioning and rebuilding services for your current machinery. If your production needs change, we can adjust your equipment to fit your exact specifications. Reusing your equipment costs far less than the purchase of new equipment and increases the value of your initial investment. Additionally, reconditioning offers more accurate and reliable productions, enhanced safety, and ease of operation.

Selling Your Machinery: One machine or an entire plant… We are always buying tube mills, rollformers, coil handling machinery and more. Our selling options include immediate cash sale, trade-in, consignment, and auction. Contact us today to learn more about our services and how we can help you achieve your selling goals.

Care is taken to provide a reliable description of this Ardcor tig mill, but please note that these descriptions are not guaranteed. Prospective purchasers are encouraged to verify crucial details. We reserve the right to correct typographical errors. View the terms and conditions of sale that apply to this Ardcor tig mill. Please be aware that all machinery is subject to prior sale.