UTUBE NUMBER: 1166

MANUFACTURER: Yoder Manufacturing Company

MODEL NUMBER: W15 Forming – W15 Reducing

SERIAL NUMBER: Y1352-62

SPECIFICATIONS:

Type: Refrigeration Mill, Carbon Steel

Line Direction: Left to Right

This machine was used to manufacture refrigeration tubes that must be reduced to increase length and maintain wall thickness.

The tube is welded at .480" (12.1 mm) and reduced to smaller sizes.

Maximum Wall Thickness .040" (1.01 mm)

Minimum Wall Thickness .028" (.711 mm)

Typical Wall: .030" (.762 mm)

Welding Speed: 125 FPM Max., Gear In Speed, No Load

Reducing Speed: 275 FPM @ 3/16" (4.76 mm)

200 FPM @ 1/4" (6.35 mm)

150 FPM @ 5/16" (7.93 mm)

ENTRY EQUIPMENT:

2,000 Lb. (1 Ton) Gantry Crane

2,500 Lb. (1.2 Ton) Double Uncoiler

Overhead Looper 2 Strand, Approximately 300 Feet Storage

Shear & End Welder

Pinch Roll Pull Out Stand, 10 HP

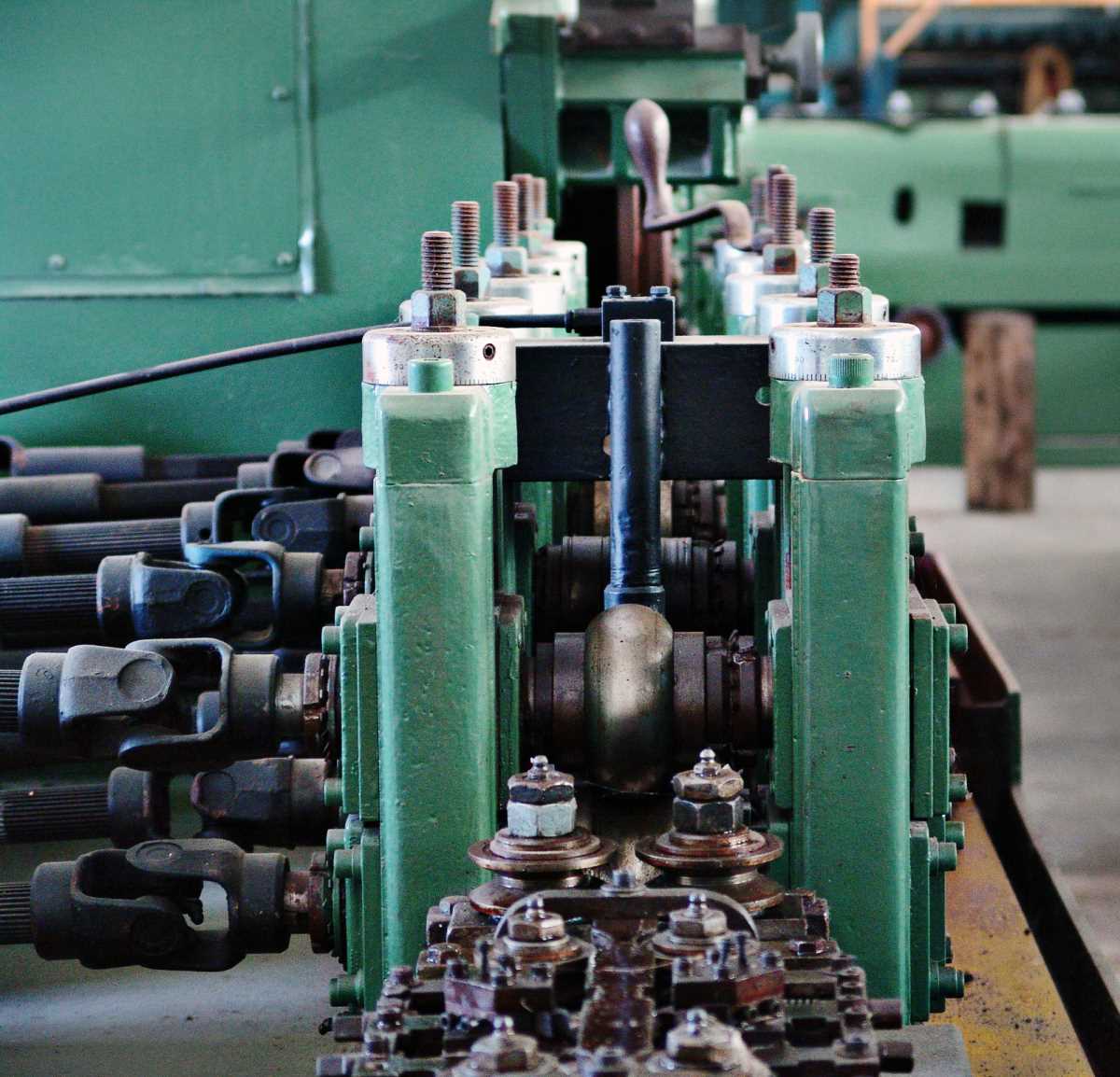

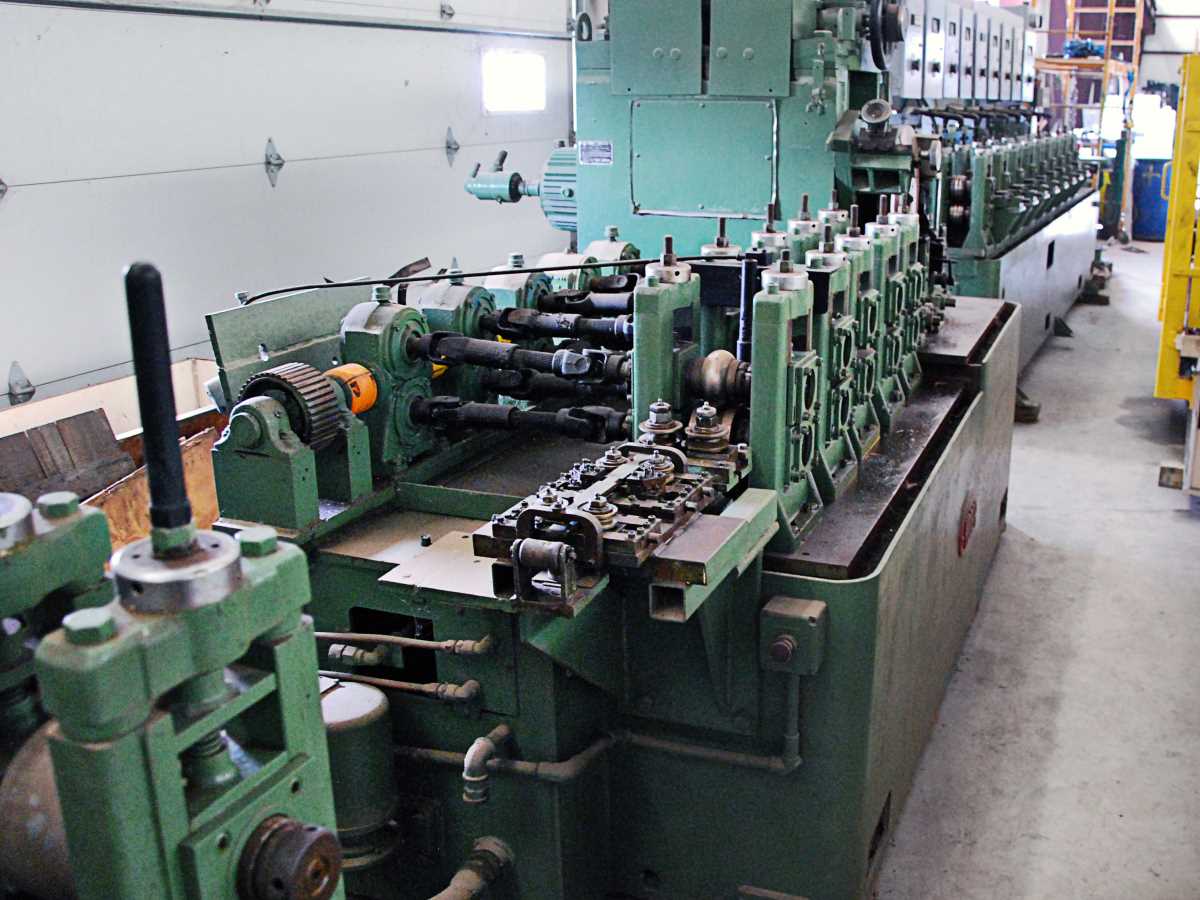

FORMING MILL:

Entry Guide Unit

(3) Driven Breakdown Stands

(2) Driven Fin Passes

(4) Idle Side Roll Units

Seam Guide Unit

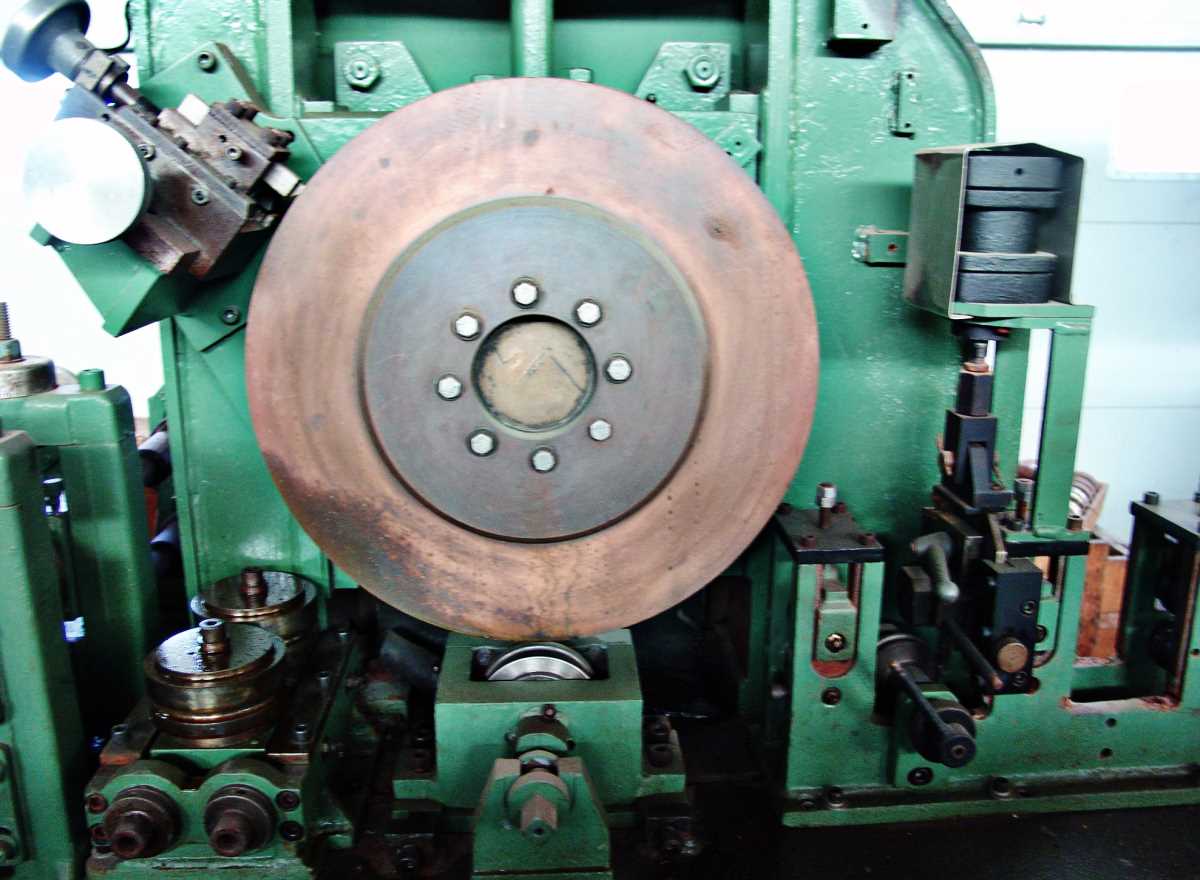

18,000 Amp. DC Welder Rotary Resistance

Scarfing Unit

Coolant Section

20 HP DC Motor

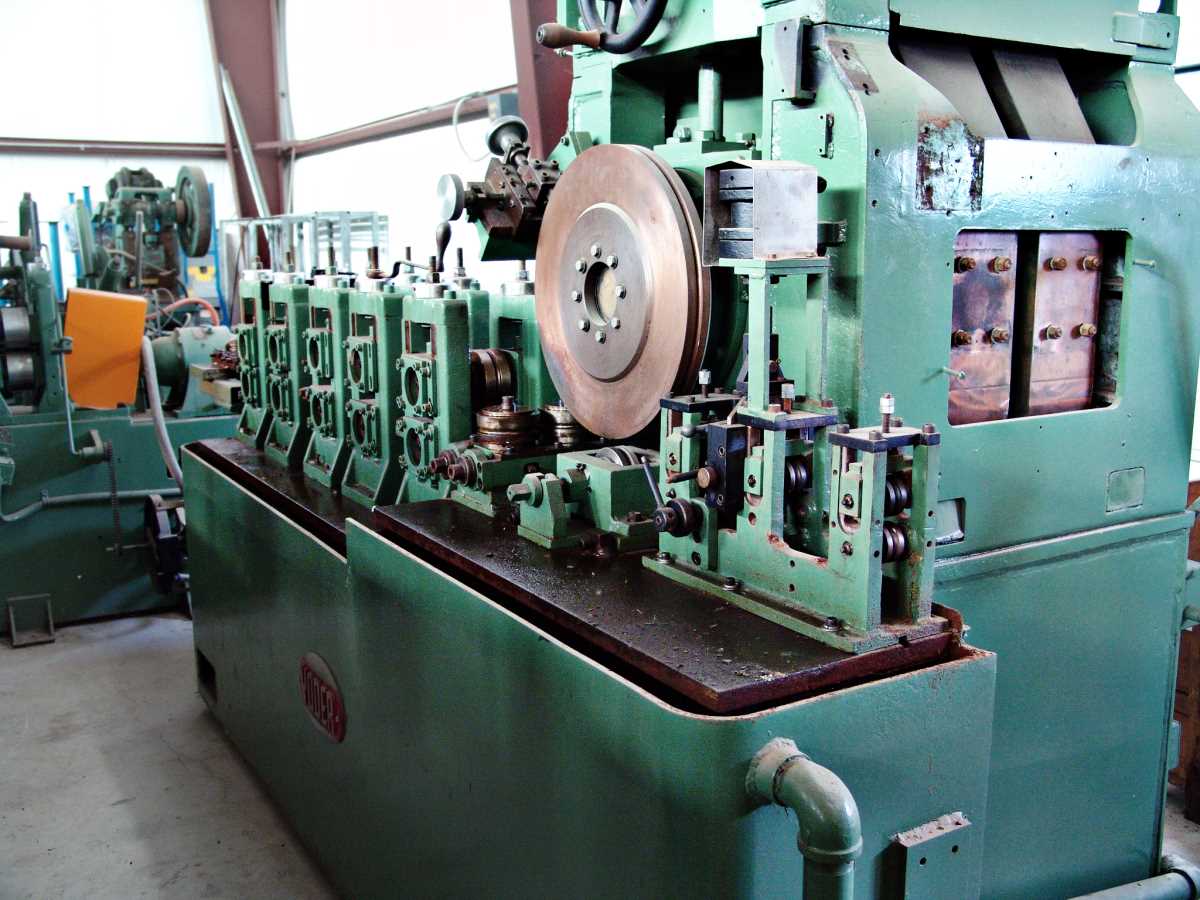

REDUCING (Sizing) MILL:

(9) Driven Reducing Stands

(9) Idle Side Roll Units

Straightener Stand

(9) 7.5 HP DC Motors

DC DRIVE SYSTEM:

WALCO Solid State DC Drive System with CUTLER HAMMER Controls

Voltage 380/3/50

TOOLING:

3/16" (4.7 mm), 1/4" (6.35 mm), 5/16" (7.93 mm)

All Produced From 1/2" (50.8 mm) Welded Tube

NOTE: Tooling is believed to be complete, but suggest customer inspection to confirm.

OVERALL DIMENSIONS: Multiple Pieces, 3 Truckloads

APPROXIMATE WEIGHT: 65,000 Lbs.

LOCATION: Universal Warehouse, Perrysburg, Ohio

Searching for a Specific Machine?

Our inventory is always changing. Contact us for help finding the machinery you need. We offer new machinery options tailored to your requirements.

Automation Solutions

We design, manufacture, and install control panels, drive systems, die accelerators, and other components for industrial metalworking machinery. Our team has over a century of experience specializing in tube, pipe, and rollform machinery. We deliver efficient and economical automation solutions worldwide.

Start-Up and Service Support

Our in-house engineering and service team offers installation management, start-up, commissioning, operator training, on-site service, and technical support. We prioritize quick machinery implementation and ongoing assistance to maintain efficiency.

Parts and Consumables

To minimize downtime, we stock common replacement parts at our Perrysburg, Ohio warehouse. Our team ensures prompt delivery to keep your operations running smoothly.

Machinery Reconditioning Services

We offer machine reconditioning and rebuilding services, updating to the latest technology, expanding capabilities, and improving performance. Reusing your equipment increases value, ensures accuracy, enhances safety, and eases operation.

Selling Your Machinery Made Easy

We purchase tube mills, rollformers, coil handling machinery, and other industrial metalworking machinery. Selling options include cash sale, trade-in, consignment, and auction. Contact us to learn more about our services and selling options.

Care is taken to provide a reliable description of this reducing tube mill, but please note that these descriptions are not guaranteed. Prospective purchasers are encouraged to verify crucial details. We reserve the right to correct typographical errors. Please read the terms and conditions of sale pertaining to this reducing tube mill. Please be aware that all machinery is subject to prior sale.