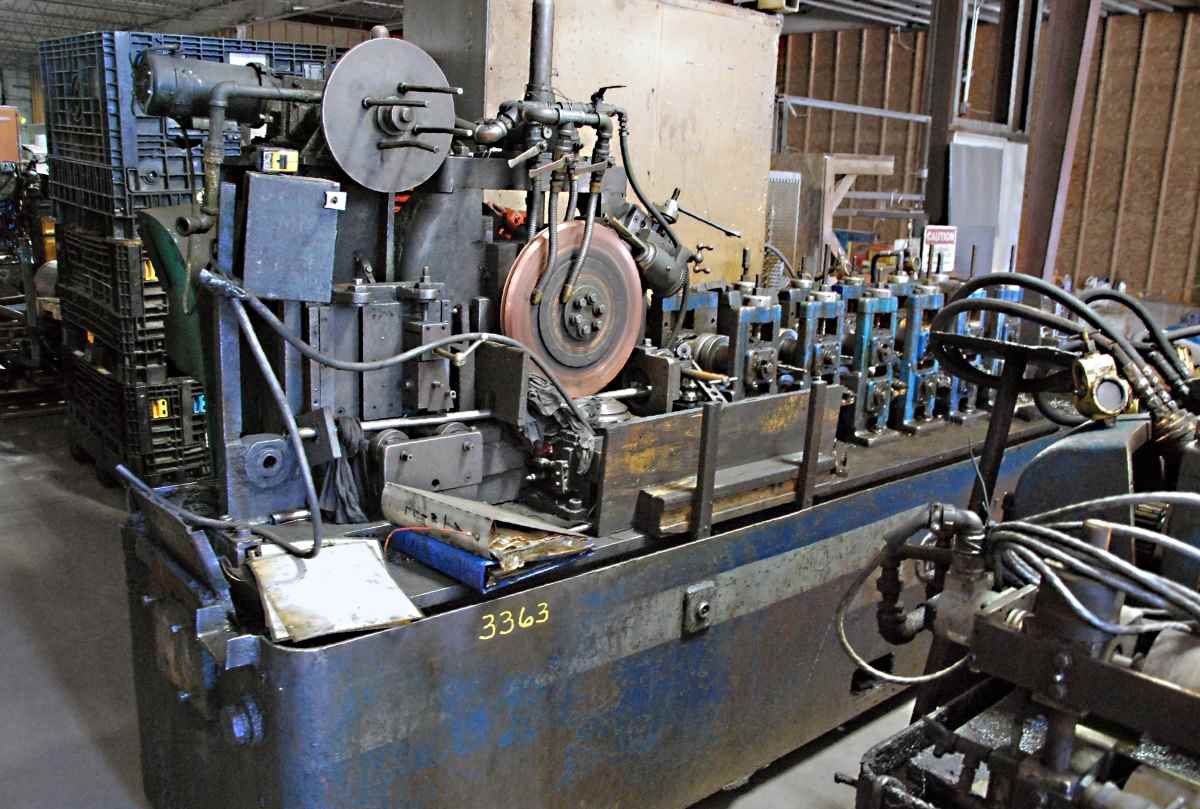

UTUBE NUMBER: 3363

MANUFACTURER: YODER

MODEL NUMBER: M1-1/2

SERIAL NUMBER: 6705

YEAR:

SPECIFICATIONS:

Line Direction: Right to Left

Maximum Tube Diameter: 1-1/4" (31.7 mm)

Minimum Tube Diameter: .313" (7.95 mm)

Maximum Wall Thickness: .049" (1.24 mm)

Minimum Wall Thickness: .020" (.508 mm)

Maximum Line Speed: 150 FPM, Max. Gear In Speed, No Load

Maximum D/T Ratio: 60:1

Minimum D/T Ratio: 10:1

Maximum Material Yield: 50,000 PSI

GEAR BOX DATA:

Spindle Diameter: 1-1/2"

Roll Space Forming, Fin & Sizing: 8"

Horizontal Centers: 11"

ENTRY EQUIPMENT:

(1) 3,000 Lb. KENT Model SKD-3000 Double Uncoiler

Serial Number: 95 – 2873 – A

Year: 1995

(1) GUILD Model PSA-2000 Shear & End Welder

(1) DMC Vertical Accumulator

Year: 2002

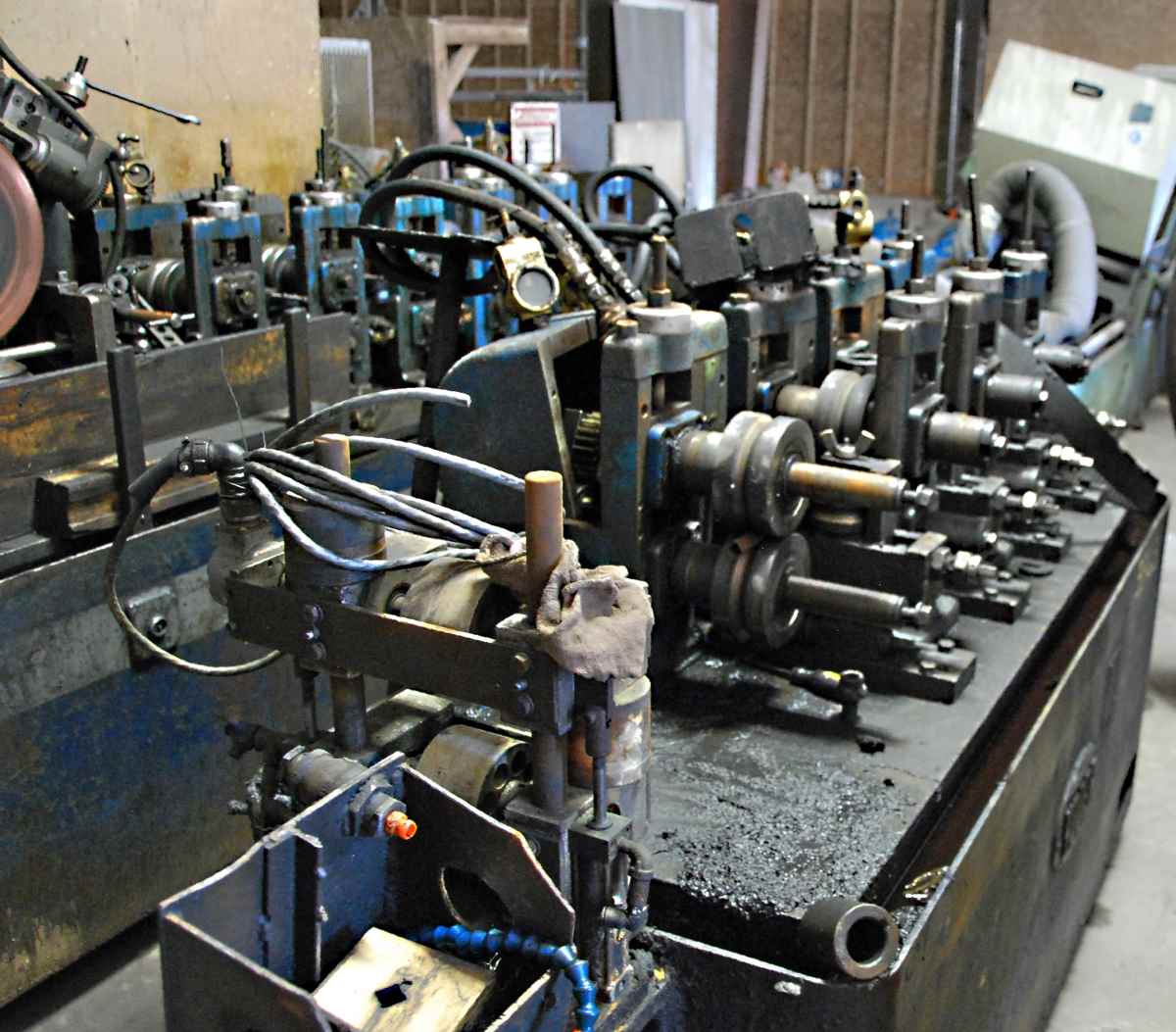

FORMING MILL:

(1) Entry Guide with (2) Edge Trimmers

(3) Driven Breakdown Stands with Oil Re Circulation

(5) Idle Side Rolls with Vertical Adjustment

(3) Driven Fin Stands with Oil Re Circulation

WELDING SECTION:

(1) YODER 75 KVA Rotary Resistance Welder with PILLAR Solid State Control

Frequency 400 – 600 Hz

(1) Seam Guide with Vertical Adjustment

(1) 2-Roll Weld Pressure

(1) Scarfing Stand

(1) Bead Winder

(1) 6′ Flood Type Coolant Section

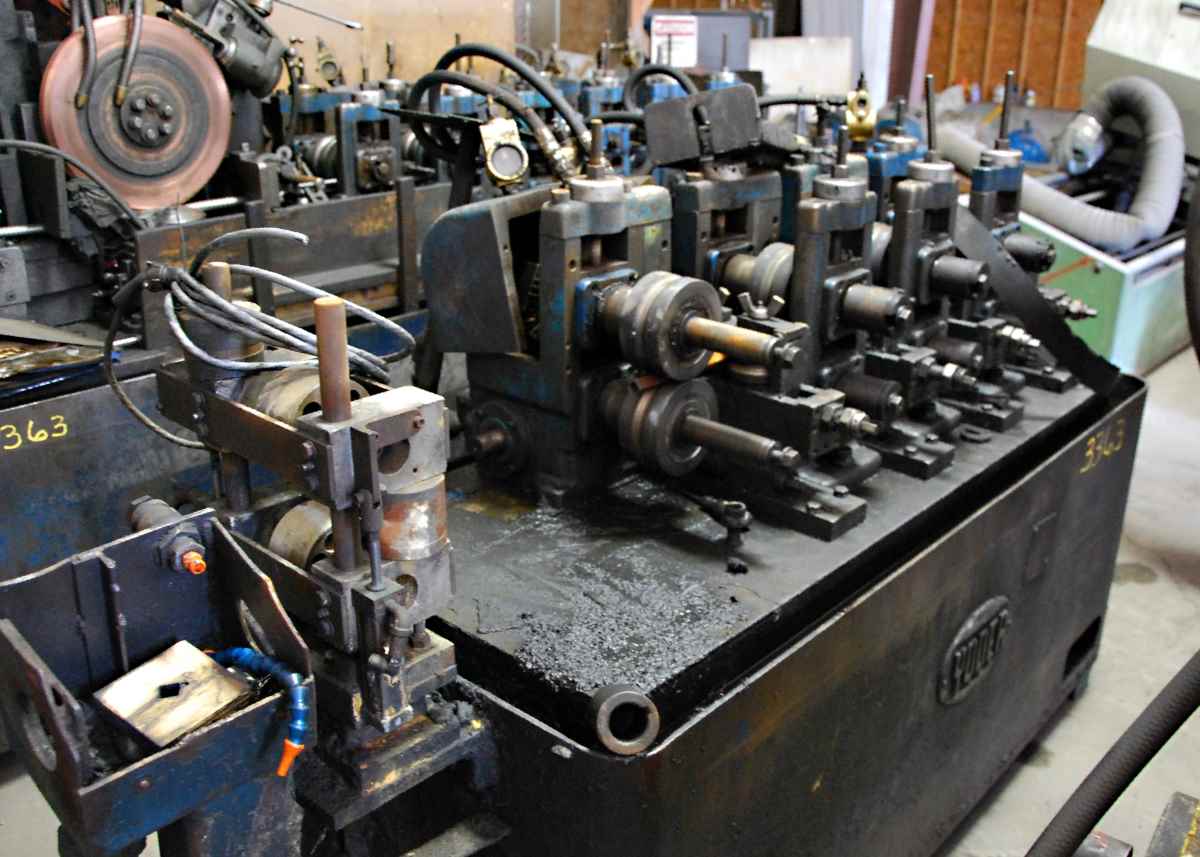

SIZING MILL:

(4) Driven Sizing Stands with Oil Re Circulation

(4) Idle Side Rolls with Vertical Adjustment

(1) Encoder Stand

CUT OFF:

(1) 4-Post YODER Model P-40 Cut-Off

Single Cut Die Set with Hydraulic Accelerator

Serial Number: 6665

Motor: 15 HP, 1145 RPM

(1) 22′ Single Dump Run Out Table

MILL DRIVE:

(1) Forming Motor, 50 HP AC, 1770 RPM, 460 / 60 / 3

(1) Sizing Motor, 50 HP AC, 1770 RPM, 460 / 60 / 3

(1) SIEMENS AC Drive Cabinet

(1) Push Button Station

EQUIPPED WITH:

Multiple Spares

Multiple Sets of Tooling

OVERALL DIMENSIONS:

APPROXIMATE WEIGHT:

LOCATION: Universal Warehouse, Perrysburg, Ohio

CARE IS TAKEN TO GIVE A RELIABLE DESCRIPTION OF THIS ERW TUBE MILL LINE BUT THESE ARE NOT GUARANTEED. PROSPECTIVE PURCHASERS ARE ADVISED TO CHECK VITAL DETAILS. WE RESERVE THE RIGHT TO CORRECT STENOGRAPHIC ERRORS. ALL MACHINERY IS SUBJECT TO PRIOR SALE. CLICK HERE TO READ OUR TERMS AND CONDITIONS OF SALE. VISIT UNIVERSALCONTROLSGROUP.COM FOR INFORMATION ON NEW CONTROL PANELS, DRIVE SYSTEMS AND PLANT AUTOMATION.