Universal offers machine reconditioning and rebuilding services for your current machinery. We can also reconfigure your equipment to the most exact specifications when your production needs change. Reusing your equipment costs far less than the purchase of new equipment and increases the value of your initial investment. Along with cost savings reconditioning also offers more accurate and reliable productions, enhanced safety, extended machine life and ease of operation. Read details below about a rollform line we reconditioned using both new and used equipment.

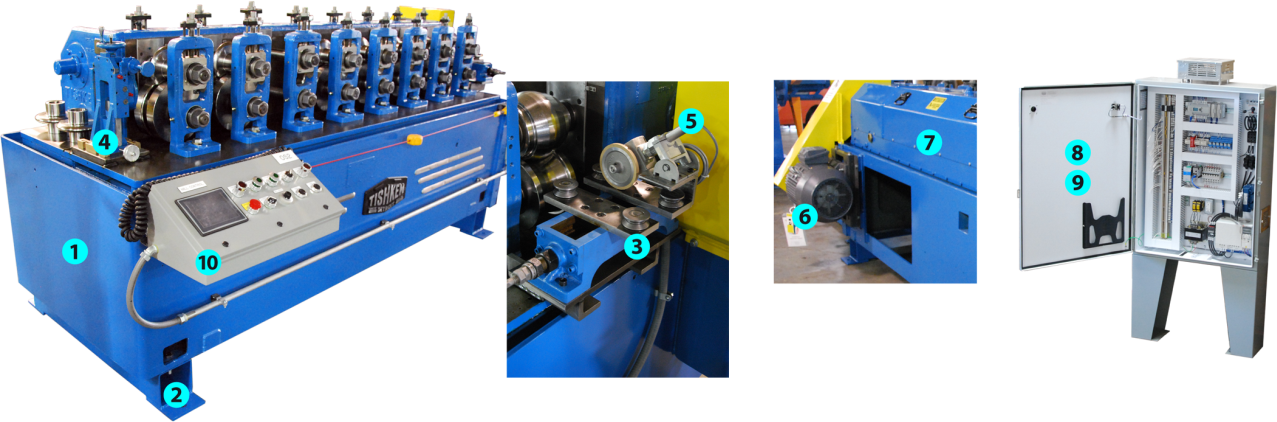

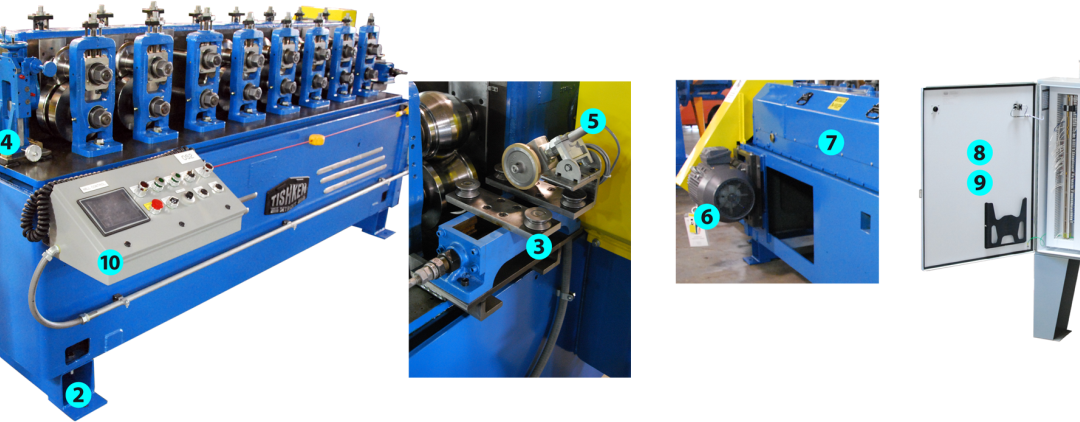

Tishken Rollformer Machine Reconditioning Details:

|

|

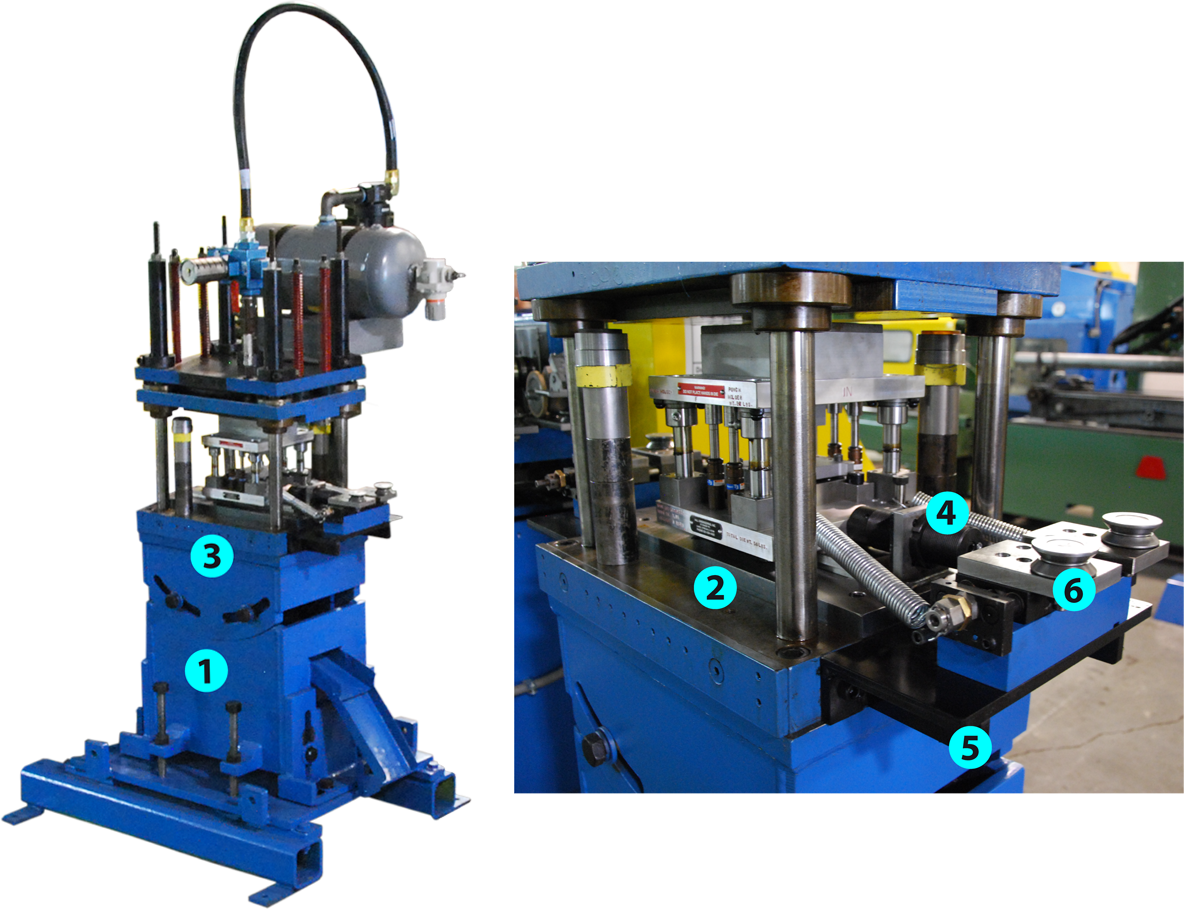

Pre-Punch Cut Off Press Reconditioning Details:

|

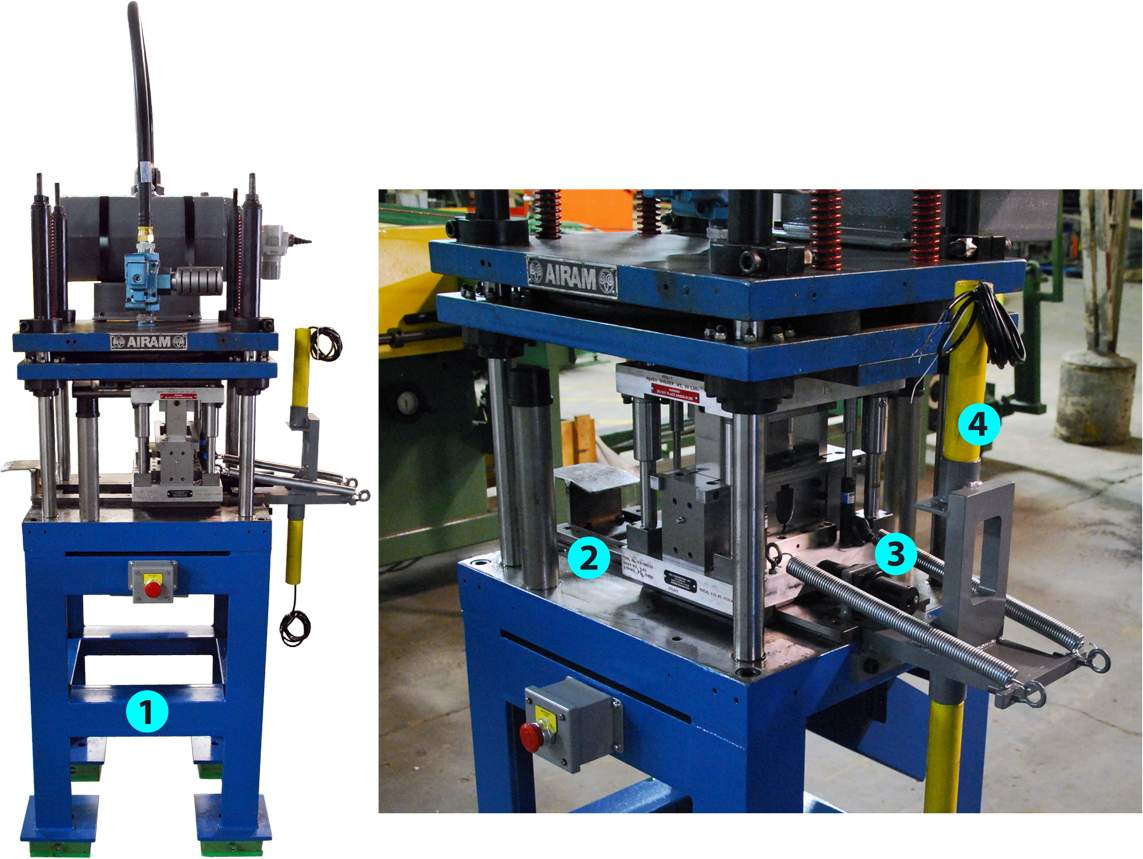

Airam Cut Off Press Reconditioning Details:

|

Universal Tube & Rollform working together with Universal Controls Group can offer you the options you need such as new controls, drive systems, cut off length control, and other accessories to retrofit your existing machinery. Whether it’s one single machine or a complete line, contact us for a quotation to reconditioning your equipment.

Hello ,

I would like to get some quote for one machine.

Se ve bien